TECHNOLOGY OF TEXTILE DYEING WASTEWATER TREATMENT

With our economic development in recent years, textile and dyeing is one of sectors has the most significant growth stats. Along with the strong development of the industry is the environmental problem arising from the production process. The stages of the textile and dyeing industry use a lot of water and generate different sources of wastewater, which vary by product. The characteristics of this wastewater have high pH, temperature, COD and relatively high color temperature. Therefore, it is necessary to have reasonable steps to treat and manage this amount of wastewater more thoroughly.

1. Characteristic of textile wastewater

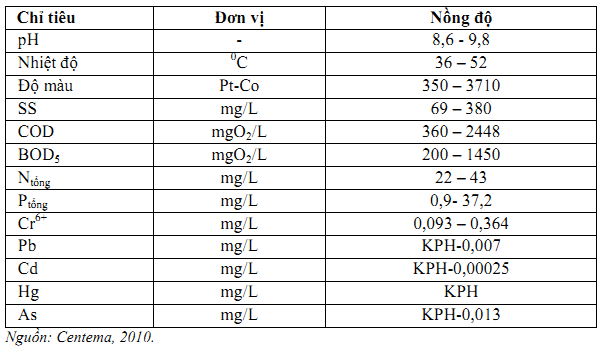

The characteristics of textile and dyeing wastewater are: High COD/BOD ratio, high temperature, the characteristics of the wastewater changes continuously per hour, the wastewater flow is always mutated, the pH of the wastewater is fluctuating, it’s high or low depends on dyeing technology and dye, high Pt/Co scale due to excess dyes entering the water, toxic content of sulfur, heavy metals, organic halogen compounds ... in the dye composition mixed with wastewater.

Table of the composition of textile wastewater

2. Basic diagram of the technological process for textile and dyeing wastewater treatment

This technological process can vary depending on the wastewater composition and requirements of each system for best performance.

3. Explanation of the process of textile and dyeing wastewater treatment

Sump: Wastewater from production activities of the plant is directed to the collection pit. Here, wastewater is concentrated and pumped wastewater pumped to the regulating tank.

Screening: to remove large objects and fine fibers in wastewater.

Air tank: Due to the unstable concentration of pollutants in the wastewater at different times, regulating tanks have the effect of regulating the flow and stabilizing the concentration of wastes before entering the system. Air conditioning tanks are powered by an aeration disc system located at the bottom of the tank to create mixing flow and maintain aerobic state in the tank.

Cooling tower: Textile and dyeing wastewater often has very high temperatures generated from various stages of the production process. Temperature greatly affects the processing stages as well as the biological process. Therefore, to ensure operation of the treatment system, wastewater needs to be passed through the cooling tower to reduce the temperature before being treated.

Reaction tank: used to mix substances with wastewater to regulate the alkalinity of the wastewater, creating a large floc with significant weight and easily settling through the settling tank I. Here, aluminum alum is used to create flakes because aluminum alum dissolves well in water, low cost.

Sedimentation tank: retains the suspended sediment (SS) present in the wastewater, the large flakes generated from the reactor will be deposited here, the sedimentation tank will reduce the solids load for the biological treatment facility. behind.

Aerobic biological tanks: In the aerobic biological tank, decomposition occurs when wastewater comes into contact with the sludge under continuous aeration conditions. Microorganisms use substrates (BOD) and nutrients (N, P) as food, convert them to insoluble inert substances and create new cells. The metabolism is done interwoven and one after another until there is no more food for the microbiota. Wastewater after aerobic biological treatment is passed through biological sedimentation tanks.

Biological sedimentation tanks: sludge generated from aerobic biological tanks and suspended substances will settle in this tank, after sedimentation wastewater is led to the sterilization tank. The amount of sludge generated from this settling tank will be discharged into the sludge tank.

Sludge presses: after passing through the sludge compressor tank, the sludge will continue to be transferred to the sludge press, this process drains most of the water in the sludge after it passes through the sludge collection tank.

Disinfection tank: treated water will automatically enter the disinfection tank and disinfectant chemicals are pumped in to terminate pathogenic bacteria such as E.Coli, Coliform , ... in the wastewater before being discharged into the environment. .

Some typical Textile and dyeing treatment projects were performed by Van Lang Company

Wastewater treatment plant of TMTC Textile IZ, capacity: 40,000 m3/day, QCVN 40:2011/BTNMT, Column A

.jpg)

Wastewater treatment plant of Nhon Trach - 6A IZ, total capacity: 120,000 m3/day, QCVN 40:2011/BTNMT, Column A

Wastewater treatment plant of Chyang Sheng Vietnam Textile IZ, capacity: 7,000 m3/day, QCVN 13 - MT:2015/BTNMT, Column A

Wastewater treatment plant of Long Binh IZ, capacity: 4,000 m3/day, QCVN 40:2011/BTNMT, Column A

Wastewater treatment plant of Sigma - Long An Textile IZ, capacity: 4,900 m3/day, QCVN 40:2011/BTNMT, Column A

Wastewater treatment plant of Thai Tuan Corporation Textile IZ, capacity: 2,200 m3/day, QCVN 13:2008/BTNMT, Column B

Wastewater treatment plant of Hoa Sen Textile and Garment Co.,LTd, capacity: 1,000 m3/day, QCVN 13:2008/BTNMT, Column B

For more related works please click here

For more WWTP which performed by Van Lang, please click here

Customer please contact for more info:

Address: 1/1, Street 5, Ward 7, Go Vap District, HCMC.

Hotline: 0946 758 660 - Mr. Hieu or 0918 203 065 - Mr. Long

Email: vanlang@vlc.vn - congtymoitruongvanlang@gmail.com

Website: vlc.vn

Fanpage: facebook.com/vlc.vn

Youtube: youtube.com/channel/UC0AzgJssqlZu8m6k4o3iCAw?view_as=subscriber

|