WASTERWATER TREATMENT OF FISHERIES INDUSTRY

1. Characteristics of wastewater from seafood-processing

Sources of aquatic wastewater includes production wastewater, industrial wastewater and domestic wastewater. The flow and composition of wastewater from seafood processing varies widely among factories depending on the source of raw materials used and the composition of substances used in the process (detergents, additives, etc). Seafood processing wastewater has high concentrations of COD, BOD5, suspended solids, total nitrogen and phosphorus. Especially, wastewater generated from catfish processing has a very high concentration of grease, from 250 - 830 mg/l. The phosphorus concentration in shrimp processing wastewater can be up to 120 mg/l.

Table of analysis results of aquatic wastewater, according to the data of the Vietnam Environment Administration:

.jpg)

2. Proposed aquatic wastewater treatment technology

Van Lang Environment Company with over 20 years of experience is proud to be one of the leading units in the field of environmental treatment, the general contractor for many projects which have the largest scale in Southeast Asia. With the motto of constantly striving to improve the quality of technology and services to satisfy customers' needs, we has built for ourselves a reputable brand in the field of environmental treatment.

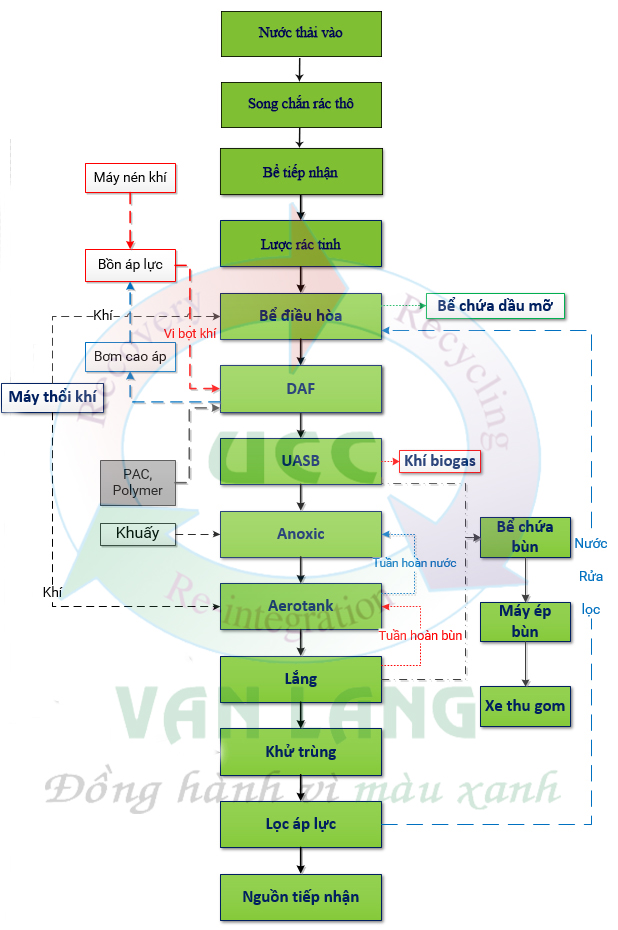

Diagram of fisheries wastewater treatment technology

Influents follow the collection system through the trash rack, large trash will be blocked here in order to avoid pipes and pumps jamed during operation.

Water flows by itself to the receiving tank and is pumped to a screen filter to separate small-sized solid wastes before flowing through the air tank.

Air tank has a aeration system working 24/24, which helps avoiding sedimentation, generating bad odors and regulating the flow and concentration of wastewater.

Then the wastewater is pumped to the flotation tank, which separates the grease and surface substances from the wastewater, and the grease will be directed to the grease tank.

Wastewater continues to flow to the UASB anaerobic tanks to conducts anaerobic decomposition.

After passing the ASB tank, wastewater is led to an anoxic tank. Anoxic tank with Aerotank, they treat synthetically: reducing BOD, reducing NH4+ and reducing NO3- to N2. With the combination of activated sludge treatment tanks and anoxic process, aerobic will take advantage of the amount of carbon when reducing the BOD, so there is no need to add carbon when reducing NO3- , saving half amounts of oxygen when nitrification reduces NH4+ due to the use of oxygen from the NO3- reduction process. Wastewater in Aerotank tanks is continuously circulated back to Anoxic tank to perform the process of reducing NO-3 in wastewater.

Microorganisms in Aerotank tanks will be added periodically from the circulating sludge in the clarifier. These microorganisms will decompose organic matter into the final product CO2 and H2O, reducing the concentration of dirt in the wastewater. In the Aerotank tank, there are more contact materials to increase the chance of contact between microorganisms and wastewater, and is the environment for microorganisms to grow and adhere.

After biological treatment, wastewater overflows to sedimentation tanks to settle the sludge and to separate the phases. Part of the sediment settles to the bottom of the tank is partly circulated to the aerobic and aerobic biological tank to maintain the concentration of sludge, the sludge will be pumped into the sludge tank.

The water is disinfected in the disinfection tank and then through the pressure filter to remove the residue that the biological sedimentation process has not yet done, ensuring the transparency of the water before going to the receiving source.

Wastewater after treatment ensures QCVN standards on aquatic wastewater.

Units, enterprenuers, companies wishing to "Design treatment system for fisheries wastewate", "Renovate treatment system for fisheries wastewate", "Consulted about fisheries wastewate treatment",... Please contact us for the best service!

For Environmental Consulting, making Registration certificate, Invesment certificate, EIA report, Environmental Protection Sheme, obtaining discharge permit, groundwater registration, Registration of hazadous waste source owner, report of completion, environmental protection method, environmental monitoring report, site work agreement, invesment report, certificate, data-gathering for projects, evaluating Impacts of waste sources, environmental method, environmental monitoring …

Procument and engineering of paper wastewater treatment system, calculating and designing paper, pulp wastewater treatment system, CAD drawing of paper wastewater treatmen, Structure of water treatment equipment, Quotation of pulp wastewater treatment system, Construction cost of paper wastewater treatment system, Economical factor of Textile Waste water treatment, Aquatic wastewater treatment, Water treatment, Industrial Park water treatment, paper manufacturing wastewater treatment, pulp wastewater treatment, Fishery wastewater treatment, Milk processing wastewater treatment, strippings wastewater treatment, Food wastewater treatment, Wastewater treatment with high suspended matter...

Construction consultancy, Construction of Wastewater treatment system, Supply water treatment, EPC General Contractor, General Construction Contractor, Environmental Consultant, Environmental Impact Assessment (EIA), Environmental Procedures, Environmental profile, Environmental monitoring consultant, Wastewater treatment system operation, Treatment system innovation, checking, free consulting for existing works at the factory ...

Customers please contact

Van Lang Industrial Waste Treatment and Environmental Consulting Company

Address: 1/1 Street 5, Ward 7, Go Vap District, HCMC

Hotline: 0946 758 660 - Mr. Hieu or 0918 203 065 - Mr. Long

Email: vanlang@vlc.vn - congtymoitruongvanlang@gmail.com

Website: vlc.vn

Fanpage: facebook.com/vlc.vn

Youtube: youtube.com/channel/UC0AzgJssqlZu8m6k4o3iCAw?view_as=subscriber

Photos of some projects performed by Van Lang General Contartor:

HUNG VUONG FISHERIES WATSEWATER TREAMENT PLANT - CAPACITY 1,500 M3/DAY

WATSEWATER TREATMENT PLANT OF CHITTIN VIETNAM FOOD - CAPACITY 600 M3/DAY

GO DANG FISHERIES WASTEWATER TREATMENT PLANT - BEN TRE - CAPACITY 1,600 M3/DAY

GO DANG FISHERIES WASTEWATER TREATMENT PLANT - CAPACITY 1,600 M3/DAY

|