| Name of product: | Screw press |

| Material: | Stainless steel SUS304 |

| Motor: | Taiwan; EU; G7 |

| Capacity: | Meet all the Clients’ requirements |

| Size: | Various sizes, can meets all the Clients’ requirements |

| Production time: | From 2 to 8 weeks |

| Certificate: | Certification of meeting the output standards for use |

| Manufacturing technology: | Producing according to tranfer technology of Partners and top Engineers in environmental field with realistically computational design modeling. |

| Warranty: | 06 months |

| Shipping: | Free shipping in HCMC |

| Price: | Contact for more info |

Screw press is a device which is used at the last phase of wastewater treatment progress. And some particular waste sludge such as: mining sludge (coal, iron plating, mineral or hard sludge) can’t be pressed by normal machines (Belt press, Filter press) but screw press.

Screw press can reduce the level of layers in sedimentation tank or thick mud tank, from that, it can help saving construction cost of wastewater treatment plants.

I. Operating principle of Screw press:

The operating principle of the screw press is to use unique spiral screws that allow dehydration and self-cleaned automatically, avoiding jam, screw press is controlled by an automatic system. This is a new technology that can be used to replace traditional machines such as Belt press or Filter press (these require high hydraulic pressure to clean filters or filter conveyors which are very water intensive ). This cleaning mechanism is ideal for dehydrating sludge that are sticky and clogging easily.

Along with that, the screw rotation speed is very low (from 2 - 4 rpm), so the power cost is also very low (0.8kW/h) and consumes less water than centrifuges. Especially, the noise level of the machine is very low as well, only 63dB after 2 years in operation.

II. Structure of screw press

The structure of the whole screw press from the frame to the internal parts are all made from special materials with corrosion resistance from acid or any waste in treatment progress.

Structure of screw press

The design of the components is extremely sturdy, operating smoothly, without causing much noise.

The screw press has a few outstanding components, includes:

- Filter is designed for efficient, non-jamming up water drainage

- Parts such as refueling, filter, outlet are designed separately, easy to dismantle. The maintenance process will be much easier.

- Easy to operate because the controller is always installed on the machine

The volume of capacity is varied, from 1m3/h - 90m3/h

- Easy to use: sludge does not need to be pre-condensed, no need for skilled workers

- Maximum power saving

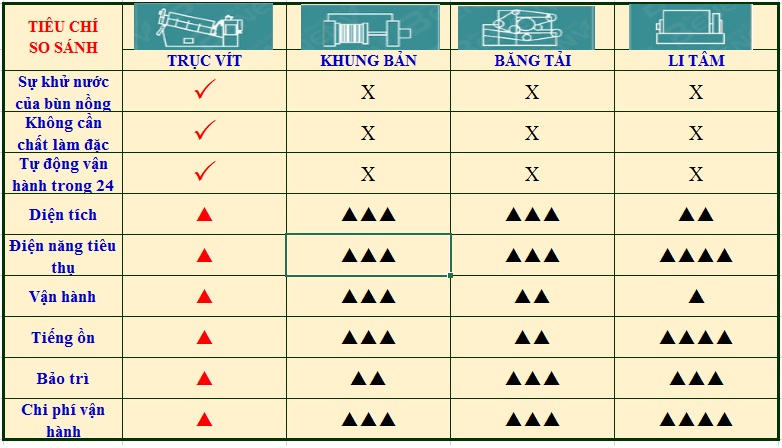

Comparing between Screw press and Filter press

III. Screw press is widely used in a number of following fields:

- Field of processing vegetable oils such as peanut oil, coconut oil or coconut milk ...

- Field of environmental treatment such as chemical sludge treatment, aquaculture ponds or waste pressing, microbiological sludge pressing, ...

- The field of food processing such as fruit pressing: pineapple, sugar cane ...

- And in the field of processing seafood by-products such as pressing shrimp shells, by-products from fish processing factories ...